OK, so, what’s the plan?

First Step: Hubs. Almost every water wheel in the world uses hubs (except of course our old water wheel in Skyforest). Gotta have hubs. It’s what makes the world go round. But, what kind and how big? I found a company in Georgia (waterwheelplace.com) which not only builds and sells water wheels of all sizes, but he also sells hubs and bearing kits. That’s my plan.

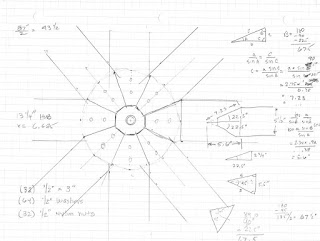

But what diameter? If I used 8 spokes, each about 5 1/2” wide and evenly spaced at 450 angles…and if I butt them all together in the center, what diameter of a hub would I need to make sure I would have enough meat on the spokes to bolt to?

But what diameter? If I used 8 spokes, each about 5 1/2” wide and evenly spaced at 450 angles…and if I butt them all together in the center, what diameter of a hub would I need to make sure I would have enough meat on the spokes to bolt to?

Ya know, during my high school and college years, I thought I would never actually use calculus, solve a differential equation, or use eigenvectors (don’t ask) in my career…and I was right! After all that studying, never once did I need to use them.

But Trigonometry…now that’s another story. Hold on to your hats…it’s math time!

In the figure above, what would be the radius if the butt-ends of the spokes were lined up together in a circle as shown? A clue: The width of the spoke is the “chord” of an arc having an angle of 450.

Using a trigonometry equation (see diagram) and the sine of 22.50 (half of 450), the radius turns out to be 6.8 inches. Hence, the diameter of the butt-ends of the eight spokes is approximately 13.6 inches. The diameter of the hub would need to be 18 - 20 inches to cover the spokes…way too big (and expensive). Obviously, the ends of the spokes need to be trimmed to make them merge closer to the center and give the hub more meat to bolt to. Since each spoke is set at 450, each side of the spoke should be be cut at 22.50.

Second Step: Type of Wood. I selected cedar. It is clear, no lose knots, kiln dried, durable against critters and weather, and it smells so dog-gone good when cutting. I ordered some 2x6’s, 1x8’s, and a 1x12 cedar.

|

| At WaterWheelPlace.com |

Nope, I think the best way is to build it in parts and assembling it in pieces on the hub and axle assembly.

...waiting for the hardware...

No comments:

Post a Comment